-

THE DIAMOND COMPENDIUM

Superbly written and researched, boldly illustrated and containing hundreds of exclusive images, The Diamond Compendium is a landmark volume in gemmological writing taking you on a fascinating journey through the magnificent mystery that is the most concentrated form of wealth on the planet and one of mankind's greatest obsessions.

Award winning gemmologist, DeeDee Cunningham, is a master of distilling scientifically complex concepts into language allowing readers of all levels of interest to understand the world of diamonds. This riveting 20 chapter, 894 page book instills insight, knowledge and wonderment as it reveals to you all of diamond's secrets. Whether you are learning the facts about purchasing diamonds, understanding the trade, preparing for formal examinations or simply satisfying your curiosity, The Diamond Compendium is a virtual diamond library in a single, visually beautiful, book.

PRAISE

"...a tremendous amount of relevant information in one reference book...recognized as the authoritative work on the subject."

Stuart M. Robertson, GG, The Gem Guide, GemWorld International.

"Impressive! Very Impressive! Covers every possible topic related to diamonds"

Gary Roskin, GG, The Roskin Gem News Report

"...a reference for gemmology and diamond courses worldwide...the definitive work on the subject"

Peter G Read, C. Eng, FGA, DGA, Author of Gemmology, Webster's Gems 5th Edition.

"...the entire curriculum in one reference, it should be the first, or next, diamond reference book to find its way onto your shelf."

Chris Holdsworth, Instructor - Diamond Technology, The Gemmological Association of Australia

"Well written and easy to understand...photographs and diagrams are both excellent...a must for any personal and professional library"

Nizam Peters, American Institute of Diamond Cutting

"Great work, excellent research and beautiful writing"

Stephen Hofer, Author, Collecting and Classifying Coloured Diamonds

"...the definitive book on diamond"

A.J.A (Bram) Janse, Archon Exploration.

"The most thorough, absorbing and comprehensive book on the market."

Howard Rubin, GG and Gail Levine, GG, National Association of Jewellery Appraisers

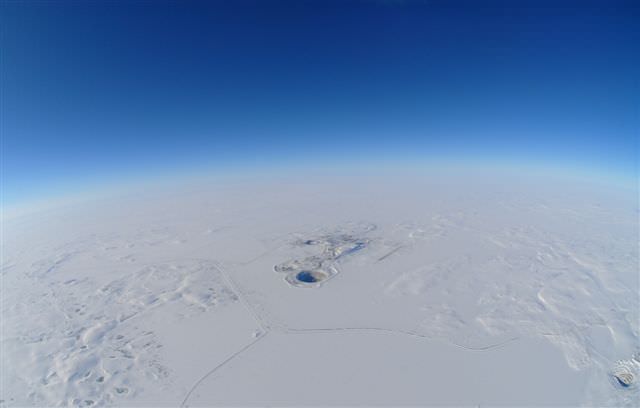

A LOOK INSIDE: LEFT: Distant view of Canada's Diavik Mine in winter showing hundreds of kilometers of ice roads to the site in the foreground. RIGHT: Aerial view of the Diavik Mine when the lake is not frozen. In non-winter months, all supplies are airlifted to the site because it is impossible to build permanent roads.

Charles Fipke began searching for diamonds in Canada's Northwest Territories in the 1970s. By 1985 he had ramped up his quest, collecting samples from a 520,000 square kilometre area of desolate Arctic tundra. His cloak and dagger operation processed the samples under a fictitious company, Norm's manufacturing, to ward off potential competitors. In 1990 he hit pay dirt with the major diamond-bearing kimberlite find at Lac de Gras, which became the Ekati Mine. In reality, there was no real secret that the diamonds were there; it was just a matter of when they would be found in worthwhile quantity because of the extraordinary expense of mining in that inhospitable environment. During the months leading up to opening the Ekati Mine it cost developer BHP Billiton over $40 million USD a month in transportation alone. In Chapter 2, travel around the world sharing in the trials and triumphs behind these discoveries in a detailed account of past, present and future sites, from the richest mines to remote small river diggings.

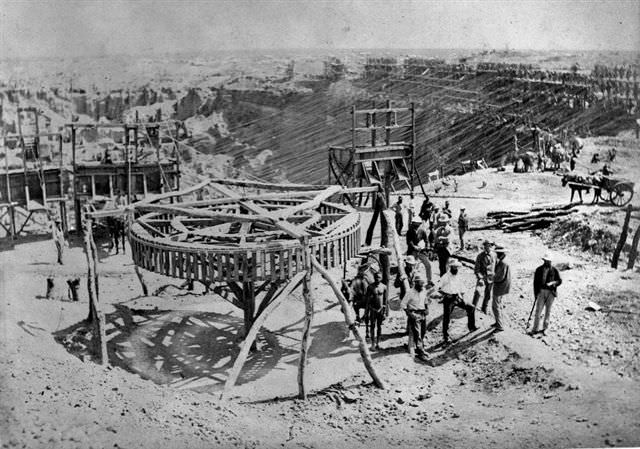

A LOOK INSIDE: LEFT: The Kimberley Mine in 1876 showing the horse-operated whim for the pulley system is in the foreground. RIGHT: Aerial view of the Cullinan Diamond Mine plant and the open pit in the background circa 2001.

Mining is one of the few methods of generating new wealth, and second only to agriculture as man's earliest endeavour. Although archaeological discoveries date mining back to Palaeolithic man 450,000 years ago, diamond mining has only been carried out for approximately 2900 years. In Chapter 4 you'll explore this captivating history from primitive pick-and-shovel methods to the high-tech operations of modern underground mines. Get to know the mining terminology, mining considerations, environmental issues, and all aspects of mine development: prospecting, exploration, development, exploitation and disposition.

A LOOK INSIDE: LEFT: a mountain of kimberlite ore for processing; notice the two tiny figures at left. RIGHT: The semi-mobile oversize primary crusher at the Jwaneng Mine, the richest diamond mine in the world. Here it sits on Bench 4 in the pit and will move as the pit becomes deeper.

Diamond recovery is different from that of other minerals because it has the lowest grade of all ores presently mined: the waste to diamond ratio is 10,000,000 to 1 and diamonds must be recovered undamaged to preserve maximum value. Chapter 6 takes an insider's look at the evolution of diamond processing technology, from pan and sieve techniques at ancient river diggings, to large scale present-day operations utilizing fully automatic control systems conducting in-stream analysis of material as it is being processed. Diamonds are recovered by a series of mechanical techniques employing scientifically based technology designed to exploit diamond's unique properties: specific gravity, affinity to grease, fluorescence to X-rays, non-magnetic nature and extreme hardness. See these operations in detail at all three steps: liberation, concentration and recovery.

A LOOK INSIDE: LEFT: The Red Shield diamond. RIGHT: Fancy green diamond with fluorescence contributing to colour.

Long ago in Roman times coloured diamonds were recognized only as curiosities. Each century since has seen increased interest to the point that in the 1900s elite members of society began collections. Then a single sale on 28 April 1987 changed their fate forever when dealer Theodore Horovitz paid a record-smashing, in fact six times the previous record, US$926,000 per carat for the 0.95 carat Hancock Red Diamond at Christie's. The enthralled public and industry never looked back. Over the last 30 years, coloured diamonds have risen in status to the pinnacle of the gem world; now enjoying status as the unrivalled king of all gemstones and the most expensive substance on earth. Fancy diamonds occur in all colour varieties: white, black, grey, red, orange, yellow, green, blue, violet, purple, brown, olive, and pink. Immerse yourself in their wonder in Chapter 8 as you begin comprehending the science of their colour, its causes, and how they are identified and evaluated.

A LOOK INSIDE: LEFT: sawing an 85 carat rough on a diamond-charged blade rotating 8000 rpm. It was polished to a 35 carat D Flawless Ashoka which premiered at Elton John's White Tie and Tiara Ball. RIGHT: the 35 carat Ashoka being facetted.

Cleaving, likened to splitting wood along the grain, is the perilous act of dividing a diamond in two along its grain by means of a sharp blow. When Harry Winston had the 601 carat Lesotho Diamond cleaved live on television in 1968 the diamond unexpectedly split into three. The third piece, 25 carats, was scooped up by an assistant so the audience never saw it. When Winston learned the misfortune was concealed he was displeased, believing it better to have let the audience experience the drama and risk. Cleaving is always perilous. The first attempt to cleave the world's largest diamond, the 3106 carat Cullinan, failed when the force broke the blade not the diamond. Tradesmen's mistakes are seldom fatal but the diamond cutter has no means of salvage. Mistakes on big stones mean multi-million dollar losses. Come and meet these cutters, who possess the steely nerves to transform a frosted irregular chunk into a dazzling creation in Chapter 9 and explore historic and modern diamond cutting.

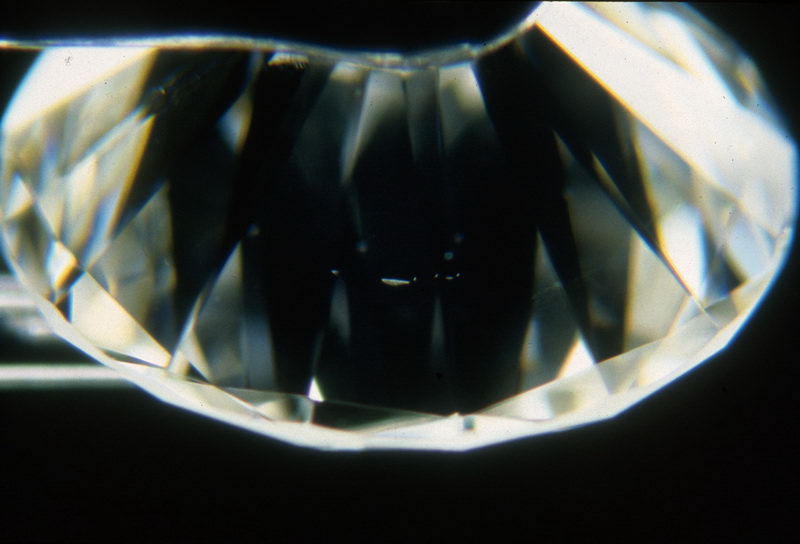

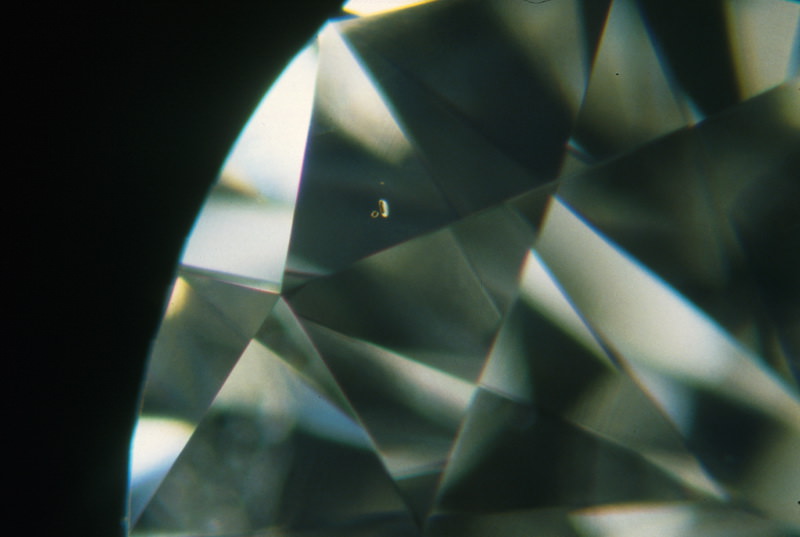

A LOOK INSIDE: LEFT: a VS1 with a small feather seen through the pavilion at 30X. RIGHT: two dark crystals as seen through the crown at 45X. The smaller is VS1 size and the larger, the grade maker, is VS2 size.

Diamond grading is a challenge because nature produces an infinite combination of features which cannot be neatly and easily assigned within the boundaries of man-made commercial diamond grades. One of the most difficult challenges for the novice clarity grader, and the one that leads to most mistakes, is not being able to master the art of considering the five factors of inclusions - number, size, position, brightness/relief and nature - simultaneously for effect on overall appearance. The greatest challenge for the colour grader is usually presented with hues other than yellow because they have saturations that inherently appear lighter or darker than that of an equal draw of yellow. Learn how to circumvent these pit falls in Chapters 11-14, a deep dive into grading: carat weight, clarity, colour and cut. Study all the fundaments, secret tips and techniques to advance your understanding and grading skills. Presented with extensive illustrations and photomasters.

A LOOK INSIDE: The 101.84ct D Internally Flawless Mouawad Splendour.

The Hope Diamond is neither the largest not the most expensive diamond in the world, but it is the most notorious. But did you know the notoriety, its supposed curse, was fabricated? Pierre Cartier perpetuated and embellished rumours about its tragic history because he was eager to sell it to an heiress, Evalyn Walsh McLean, who had a fascination with the ill-fated. He went so far as to include a clause in the $184 000USD sales agreement that if any fatality occurred in her family within six months of the sale, he would refund her money on return of the diamond. His plan worked. She bought the stone and immediately took it to a Catholic priest to have it exorcised. Chapter 16 is a spellbinding history of famous diamonds. Behind fabled diamonds are the lives of Kings and Queens; leaders and industrialists; thieves and scoundrels. Get to know the tales of fortune and fate; destiny and disaster; and romance and rebellion that abound in the histories of these magnificent jewels of historical lineage and of unusual size and colour.

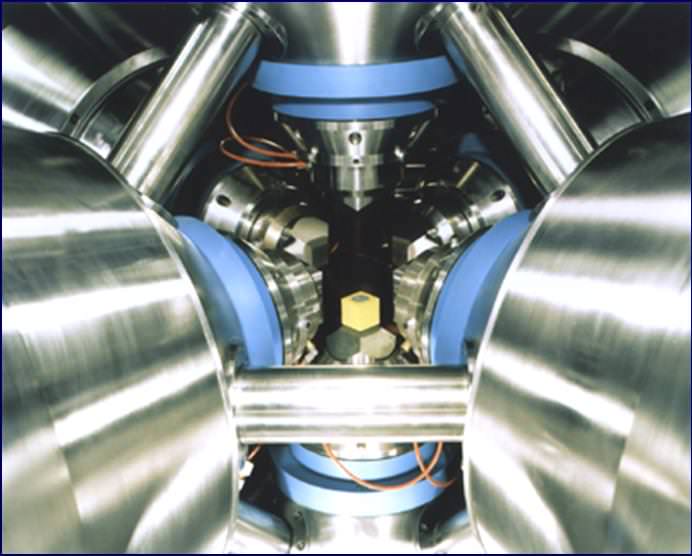

A LOOK INSIDE: Close-up of a 1200-ton cubic press constructed of six massive carbide anvils. At temperatures of 1500 ?C and pressures of 60 000 atmospheres the press yields a single bullet-shaped synthetic diamond drill piece.

In 1797 Smithson Tennent proved diamond to be pure carbon and for the next 150 years, around the globe, scores of brilliant scientists fanatically pursued diamond synthesis while risking life and limb with volatile experiments. Follow the exhilarating account of their trials in Chapter 20 and share in the glory of General Electric's success with code-named "Project Superpresssure" in 1954. By the time all was said and done, it would take materials experts in carbides and ceramics, skilled machinists, expert electricians, analytical chemists, experimental physicists and undoubtedly GE's greatest attribute - deep, deep pockets. Learn that as valued as natural diamond is as a jewel, synthetic diamond is equally revered for its high-tech applications in space, optics, thermal management, forensics, coatings, and cutting and grinding.

Loading...